News release

From:

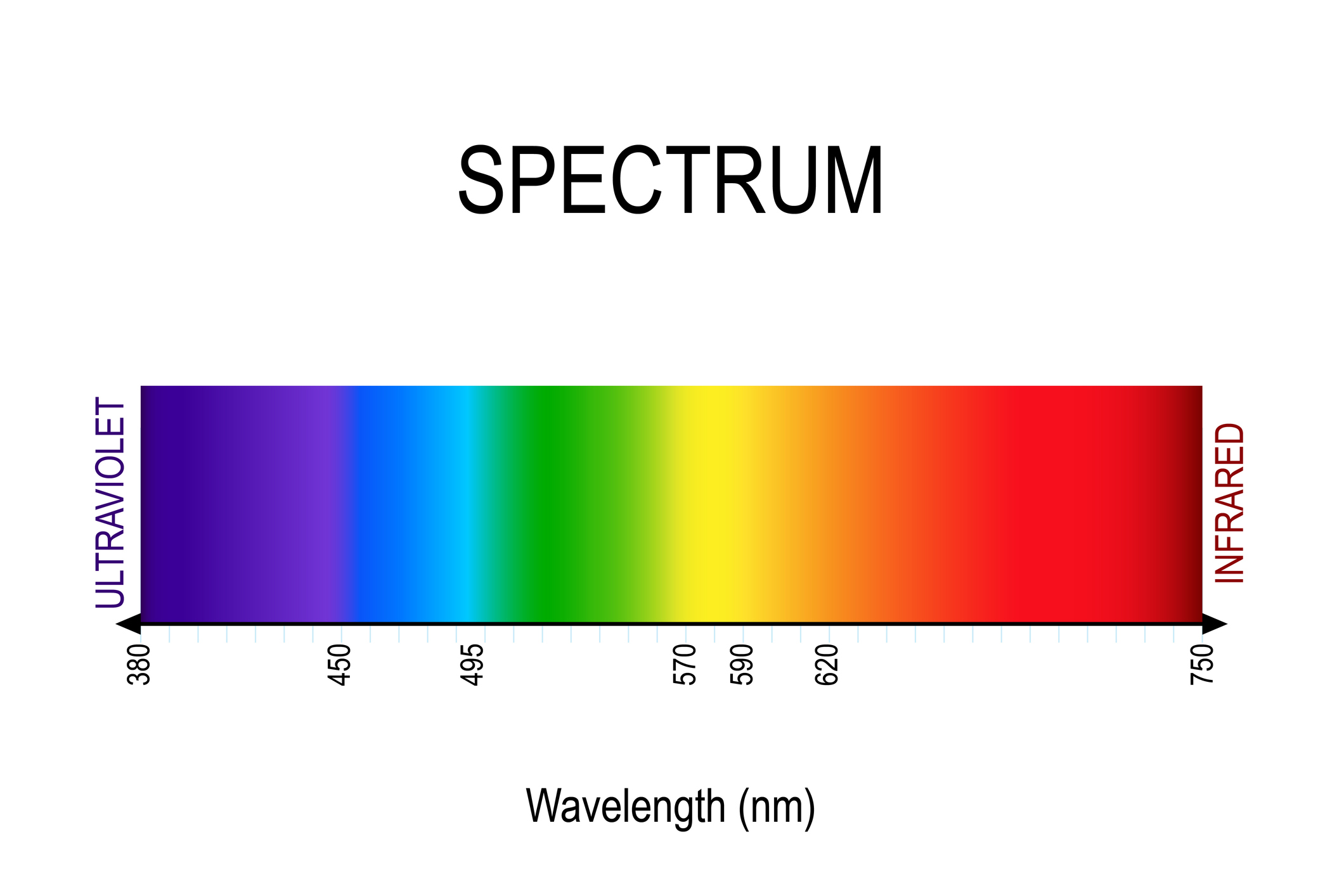

For the first time, scientists have used ultraviolet (UV) light, a low-cost and readily available energy source, to successfully synthesise more sustainable and recyclable polymer materials.

Led by green chemistry experts at Flinders University, and published in the high-impact Journal of the American Chemical Society, the development is a major step in making polymers high in sulfur content for more sustainable plastic alternatives using waste materials.

Over the past decade, the Flinders University team has shown these highly flexible sulfur-rich polymers can be used in a wide range of high-value applications – from heavy metal land and water remediation as well as optics for infrared imaging and even novel antimicrobial agents. The latest research promises to make them even more adaptable and affordable.

“We show these remarkable new polymers can be produced in more sustainable ways, and also recycled using low-cost accessible energy sources including UV light and LEDs, as well as using other methods,” says lead author Australian Research Council Discovery Early Career Research Award (DECRA) Fellow Dr Thomas Nicholls, from the College of Science and Engineering at Flinders University.

In the latest study, an interdisciplinary team from Flinders University, the University of Tasmania and Deakin University was able to produce sulfur-rich polymers by simply shining ultra-violet (UV) light on the monomer building blocks to connect them together.

The newly developed method also used pulsed LEDs (energy efficient light emitting diode) to synthesise the polymer and increase its green credentials.

“While the UV light breaks sulfur-sulfur bonds to begin with, we used short bursts of LED irradiation to overcome degradation during polymerisation,” explains Dr Nicholls. “This technique allowed the synthesis of high molecular weight polymers which allowed them to be used in several applications such as recyclable adhesives, new photoresists for lithography, and anti-corrosion coatings.”

World production of hundreds of millions of tonnes of plastic every year is creating monumental environmental problems, with many non-degradable and using toxic chemicals. The power used in producing non-organic plastics is also a contributor to pollution and global warming.

The research project team used UV light, or heating above 150 °C, to depolymerise and recycle the polymers – making it possible for the monomer building blocks to be polymerised again and reused.

Coauthor Dr Jasmine Pople says the team’s latest discovery enables the synthesis of high molecular weight sulfur polymers by simply switching on and off a light.

“This approach encompasses mild, safe, and sustainable conditions, providing ready access to sulfur polymers,” says Dr Pople.

Another Flinders University author, Dr Harshal Patel, says the application of flashing light at a steady 60 beats per minute was “an exciting project, exploring yet more applications for chemical recyclability of these polymers, as well as the mechanistic analysis”.

The article, ‘Making and Unmaking Poly(trisulfides) with Light: Precise Regulation of Radical Concentrations via Pulsed LED Irradiation’ (2025) by Thomas P. Nicholls*, Jasmine M. M. Pople, Madison R. Harvey, Harshal D. Patel, Abigail K. Mann, Samuel J. Tonkin, James D. Randall, Athulya Wickramasingha, Jiao Yu J. Wang, Johnathon C. Robertson, Le Nhan Pham, Jason R. Gascooke, Luke C. Henderson, Christopher T. Gibson, Witold M. Bloch, Sara J. Fraser-Miller, Darryl B. Jones, Zhongfan Jia, Michelle L. Coote, Alex C. Bissember and Justin M. Chalker was published in JACS, the flagship journal of the American Chemical Society and the world's preeminent journal in all of chemistry and interfacing areas of science. DOI: 10.1021/jacs.5c15051

Footnote: Dr Nicholls has just been awarded a $500,000 federal government AEA grant to scale-up the gold extraction and recovery technology which uses a low-cost polymer sorbent to remove gold from ore or electronic waste. The Australia’s Economic Accelerator Ignite grant will be done in partnership with Adelaide Control Engineering. More photos at the Flinders University lab:

https://drive.google.com/drive/folders/1n1t1zdPd6dhw4yzSu9pthIsaWnHv-rEd

Multimedia

Australia; VIC; SA; TAS

Australia; VIC; SA; TAS