News release

From:

Scientists at the University of Sharjah report that they have successfully transformed desert sand into construction bricks that are more sustainable than conventional cement or fired-clay bricks. Their innovation heralds a promising alternative to Portland cement, which accounts for up to 10% of global carbon dioxide emissions.

Once scaled up for industrial production, the new bricks could furnish the global construction industry with an urgently needed alternative to conventional construction materials. The pioneering innovation is of particular significance for the oil-rich region, where the scientists are based.

The sand deserts in the Gulf countries present a practical paradox: though surrounded by almost boundless swathes of desert sand, much of it is not suitable for farming due to lack of water. Moreover, it has long been considered unsuitable for use as a construction material without extensive and costly processing.

The scientists describe their innovation along with the process of how they manufacture the new bricks in a study titled “Production of Eco-Friendly Desert Sand Bricks Using Alkali-Activated Binders” and published in the Journal of Materials in Civil Engineering.

“In this study, we produced bricks using UAE desert sand combined with alkali-activated binders, a promising alternative to traditional Portland cement that can incorporate industrial by-products such as blast-furnace slag and fly ash,” said Mohamad Arab, Professor of Geotechnical Engineering at the University of Sharjah in the United Arab Emirates (UAE).

He explained that these binders rely on alkaline solutions “to trigger chemical reactions that form strong, rock-like binding phases.” Importantly, the bricks “were cured under ambient temperature,” the advantage that makes them commercially feasible, contrary to “similar systems that require heat curing,” a process that increases costs and energy consumption.

Desert sand as sustainable building material

The researchers used natural desert sand collected from the Sharjah region in the UAE to investigate the “feasibility of alkali-activated binders (AABs) in producing environmentally friendly bricks from local desert sand compared with OPC-based bricks.”

Created by mixing Portland cement, other aggregates, and water, OPC-based bricks are the global standard building material due to their durability and high strength as well as their suitability for rapid construction. However, despite being more eco-friendly than traditional clay bricks, OPC bricks still carry a significant carbon footprint.

The fact that many conventional bricks come with a heavy climate cost motivated the scientists to explore other alternatives for the construction sector, one of the most resource-intensive industries in the world. The authors note that construction is “a major contributor to worldwide carbon dioxide (CO₂) emissions and climate change,” consuming approximately 40% of global energy.

Their experiments using desert sand from the Sharjah region in the UAE show strong potential for producing durable masonry units from locally available desert sand combined with industrial by-products, reducing reliance on carbon-intensive materials and energy-heavy production processes.

“The broader strategic goal is clear: developing building materials that are locally sourced, resilient in harsh environments, and aligned with sustainability objectives, without compromising performance,” said Maher Omar, Professor of Civil Engineering at the University of Sharjah.

He went on, “We also evaluated performance under aggressive chemical exposure and found that the alkali-activated desert sand bricks retained their integrity and, in key cases, outperformed cement-based bricks under sulfate attack. This matters in coastal and marine environments where sulfate-rich soils and groundwater can accelerate deterioration.”

Outperforming conventional bricks

The researchers found that their desert sand bricks outperform traditional bricks, whether made of Portland cement or fired clay varieties, across key areas, including energy use, cost, and most notably, environmental impact. They emphasize that their innovative AAB-based bricks directly address long-standing challenges in the brick industry, such as “high material costs, inefficient production methods, and energy consumption in the manufacturing process.”

They write, “Additionally, bricks made with AAB and desert sand had improved durability, as indicated by their resistance to sulfate attack, surpassing that of OPC-based bricks. The results presented herein validate the suitability of bricks made with AAB and desert sand as an ecofriendly building material and highlight their capacity to reduce the construction sector’s carbon footprint significantly.”

Prof. Omar further highlighted that the new bricks demonstrated higher mechanical performance than conventional cement-based bricks, along with lower water absorption, an important indicator of long-term durability.

“We also evaluated performance under aggressive chemical exposure and found that the alkali-activated desert sand bricks retained their integrity and, in key cases, outperformed cement-based bricks under sulfate attack. This matters in coastal and marine environments where sulfate-rich soils and groundwater can accelerate deterioration.”

When asked about the study’s strategic aim, Prof. Omar explained, “The broader strategic goal is clear: developing building materials that are locally sourced, resilient in harsh environments, and aligned with sustainability objectives, without compromising performance.”

High performance and eco-friendly

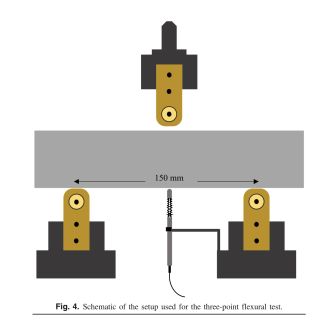

The authors emphasize that the performance of the new bricks was rigorously validated through durability tests, including “water absorption, wetting and drying cycles, and efflorescence.” They report that the “AAB bricks met all ASTM standards,” including their strong resistance to sulfate attack, as well as severe weather conditions.

The study carries considerable implications for the construction sector, with the new bricks meeting the criteria set by ASTM standards, the globally accepted benchmarks for safety, performance, and high quality across materials, systems, and manufacturing, demonstrating compliance with high-quality international criteria.

“What many people see as waste or unusable material, like desert sand, we can transform into construction and building material,” said Prof. Arab. “Instead of treating desert sand and industrial by-products as waste, we can turn them into durable bricks.”

The research’s most important takeaway for the construction section is the feasibility of producing sustainable masonry using abundant local desert sand and industrial by-products rather than relying heavily on ordinary cement. Prof. Omar added that the bricks’ ambient‑temperature curing method offers further environmental advantages:

“As these masonry units are cured under ambient conditions, the process avoids heat-based manufacturing, reducing energy demand and associated emissions. Overall, this shows the possibility for producing building materials that are locally made with lower environmental impact and potential cost advantages.”

Eyes on industrial-scale production

The authors are now focused on moving from laboratory success to real-world application. Their next step is to scale up to larger units and conduct pilot-scale testing to verify performance and ensure quality consistency under practical manufacturing conditions, an essential proof of concept for eventual large-scale production.

In addition, they plan to carry out a comprehensive commercial and cost analysis, including estimating production costs, designing, and optimizing the manufacturing workflow, and defining the logistics required for industrial implementation.

“We will also quantify the environmental benefits more clearly so we can identify the most practical and scalable pathway for industry adoption,” Prof. Omar maintained.

Multimedia

International

International