Media release

From: Griffith UniversityA new transdermal drug delivery using pulsating, fabricated microneedles present a promising alternative to traditional subcutaneous injections.

The PIDES – pulsating in situ dried electro stretching - method, developed by Griffith University and University of Newcastle researchers, developed the needles to be less than 1mm in length to painlessly penetrate the outer layer of the skin and deliver medication into the body.

“Existing fabrication methods such as micro moulding, wet etching and 3D printing are often complex, expensive and may not be ideal for some temperature sensitive drugs,” said Luan Mai, a PhD candidate and co-author of the study.

"We wanted to make microneedle production simpler, more efficient and better suited for drug delivery,” said Dr Yuen Yong, a co-author from the University of Newcastle.

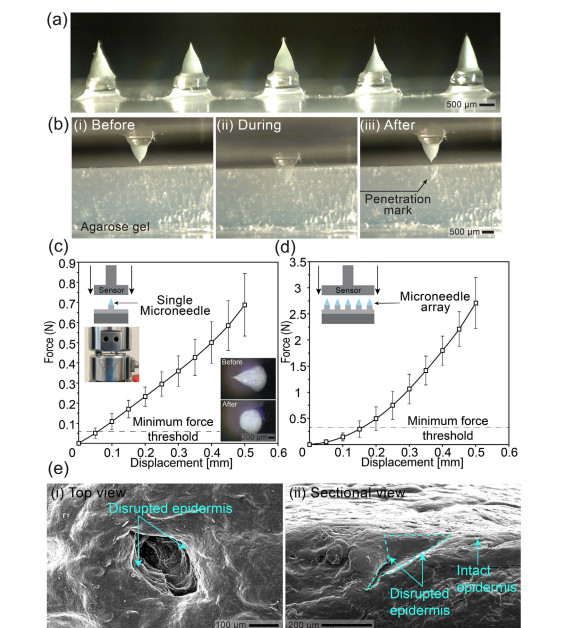

The team’s technique used pulsed electro hydrodynamic force generated between two metallic plates to stretch and shape polymer droplets into fine conical structures.

As the solvent evaporated, the polymer solidified into a microneedle with a sharp and rigid tip, ideal for painless skin penetration.

The researchers tested these microneedles on agarose gel and pig skins, confirming their mechanical strength and ability to pierce skin effectively.

They also tested drug encapsulation using curcumin, a model compound, and demonstrated a controlled time-dependent drug release profile, confirming the system's compatibility with physiological conditions.

“Our technique represents an alternative way in microneedle manufacturing,” said Dr Van Dau, from Griffith University’s School of Engineering and Built Environment.

“By integrating in situ drying with electrostretching, we’ve simplified the process while ensuring high performance, repeatability, and drug compatibility.

“The PIDES technique is low cost and scalable, allowing multiple microneedles to be fabricated without compromising quality.”

Looking ahead, the team planned to further optimise the technique and explore the development of an on-demand microneedle array system, aimed at enhancing flexibility and precision in drug delivery applications.

Dr Dau said it could lead to new pathways to more accessible and patient-friendly treatments for drug delivery, however the project was still in its early stages.

The study ‘Fabrication of Microneedles by Pulsating In Situ Dried Electrostretching for Transdermal Drug Delivery’ has been published in Small Methods.