News release

From:

Microbiology: Bacteria with a plastic-based diet may help reduce waste *IMAGES*

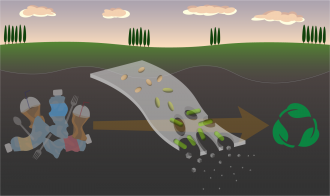

A type of plastic embedded with microbes that can help to rapidly degrade it after coming into contact with soil, is described in Nature Communications. The bacterial spores remain dormant during the useful lifetime of the plastic but awaken and help to break it down once it is no longer needed. The authors suggest that this potentially scalable approach may offer hope in mitigating global plastic pollution.

Thermoplastic polyurethanes are a type of plastic widely used in products such as phone cases, footwear, and automotive parts. However, there is currently no recycling stream for polyurethanes and most end up as waste in landfills or leach into the environment at the end of their useful life. Traditional efforts to develop biodegradable polyurethanes usually compromise the mechanical properties of the polymer and are therefore difficult to scale to industrial production.

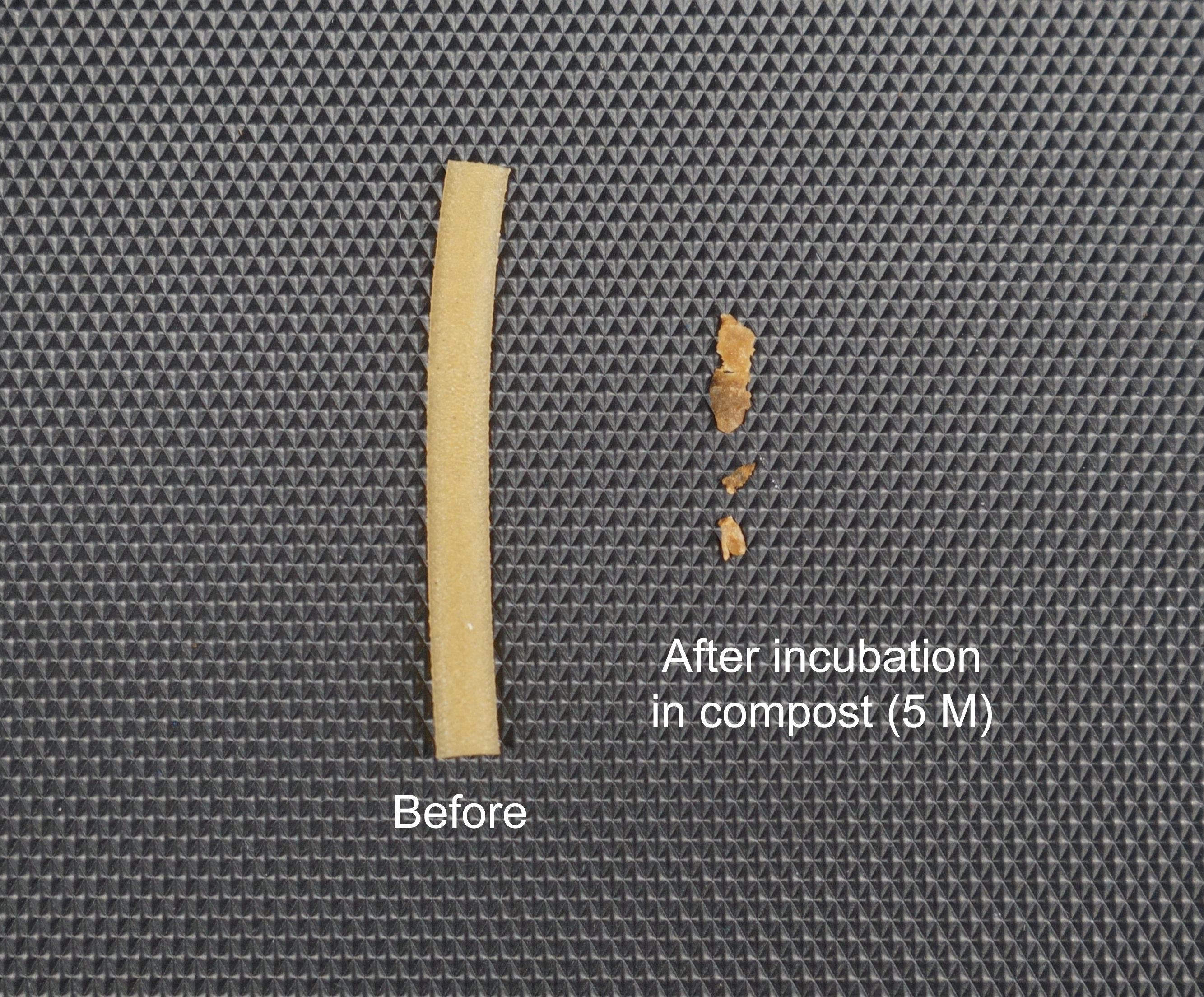

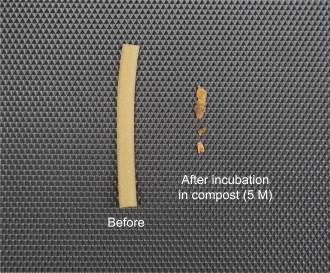

Jonathan Pokorski, Han Sol Kim and colleagues developed a biodegradable version of the commercial plastic polyurethane by embedding the spores of a plastic-degrading bacteria, Bacillus subtilis, into it. The authors genetically engineered the bacteria to tolerate the extreme heat needed to produce the plastic, resulting in nearly complete viability of the spores at the 135°C plastic processing temperature. Upon disposal in a simulated environment, rapid biodegradation of the plastic was triggered by exposure to certain nutrients in compost. The authors found that spore incorporation led to more than 90% plastic biodegradation in 5 months. It also increased the toughness of the plastic by about 37%, compared to thermoplastic polyurethanes without spores.

The authors suggest that polyurethanes containing bacterial spores could represent an environmentally promising, mechanically tough, and fast-degrading alternative to conventional unrecyclable thermoplastic polyurethanes.

Multimedia

International

International