Media release

From:

Archaeology: Concrete evidence for Roman construction techniques

Building materials found in partially constructed rooms in Pompeii offer clues into how ancient Romans made cement, according to research published in Nature Communications. These insights improve our understanding of ancient Roman technologies that have kept structures standing for centuries.

Much of our knowledge of Roman construction techniques relies on written accounts, because the discovery of tools and raw materials from archaeological sites has been relatively limited and fragmentary. It was previously thought that they relied heavily on the use of slaked lime (heated limestone mixed with water). However, recent research has pointed to a process known as ‘hot mixing’, in which quicklime (dry, heated limestone) is mixed directly with water and volcanic rocks and ash. This produces a chemical reaction that heats the mixture. Archaeological evidence directly supporting use of this method has yet to be found.

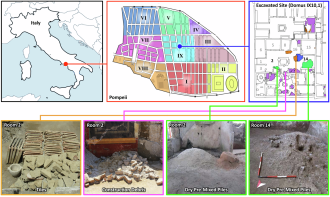

Admir Masic and colleagues examined recently excavated rooms in the Roman city of Pompeii to clarify this process. The rooms were under active construction when it was abandoned owing to volcanic activity in 79CE, preserving containers of concrete construction materials and tools where workers left them. The authors identified quicklime, volcanic ash, and aggregates — all materials that support the use of the ‘hot mixing’ technique. They also found weights and measurement tools, which they suggest could have been used to ensure consistent ratios for concrete pouring and ensure straight, level walls. The authors also analysed the chemical composition and microstructure of these building materials. They found a distinctive molecular signature and pattern of cracking and porosity which could be directly linked to the application of quicklime and hot mixing techniques on the site. The authors infer from the data that workers in Pompeii were using ‘hot mixing’ techniques in construction at the time of volcanic activity.

This work leverages a unique combination of ancient literature, archaeology, and materials science to inform our understanding of Roman construction techniques. The authors suggest that the insights gained here could be applied to modern construction processes with the aim of generating more durable and sustainable concrete.

Multimedia

International

International