News release

From:

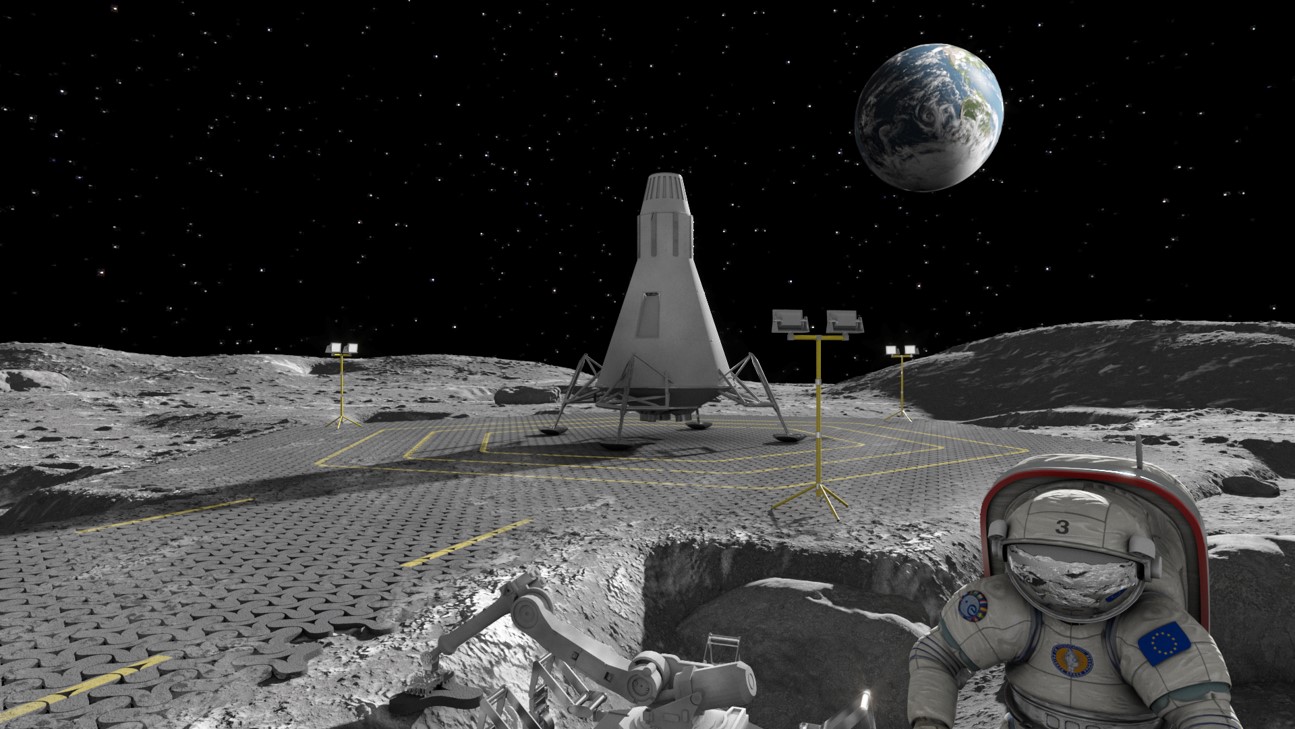

It may be possible to create paved roads and landing pads on the Moon by using lasers to melt lunar soil into a more solid, layered substance, reports a proof-of-concept study in Scientific Reports. Although these experiments were carried out on Earth using a substitute for lunar dust, these findings demonstrate the viability of the technique and suggest it could be replicated on the Moon. However, further work may be needed to refine the process, according to the authors.

Moon dust poses a significant challenge to lunar rovers as, due to the low levels of gravity, it tends floating around when disturbed and can damage equipment. Therefore, the infrastructure such as roads and landing pads will be essential to mitigate dust issues and facilitate transport on the Moon. However, transporting materials for construction from Earth is costly, so it will be essential to use the resources available on the Moon.

Ginés-Palomares, Miranda Fateri, and Jens Günster melted a fine-grained material called EAC-1A (developed by ESA as a substitute for lunar soil) with a carbon dioxide laser to simulate how lunar dust can be melted by focused solar radiation on the Moon into a solid substance. The authors experimented with laser beams of different strengths and sizes (up to 12 kilowatts and 100 milimetres across respectively) in order to create a robust material, although they established that criss-crossing or overlapping the laser beam path led to cracking. They developed a strategy using a 45 millimetre diameter laser beam to produce triangular, hollow-centred geometric shapes approximately 250 millimetres in size. These could be interlocked to create solid surface across large areas of lunar soil which could serve as roads and landing pads, suggest the authors.

To reproduce this approach on the Moon, the authors calculate that a lens of approximately 2.37 metres squared would need to be transported from Earth to act as a sunlight concentrator in place of the laser. The relatively small size of equipment needed would be an advantage in future Moon missions.

International

International