Media release

From:

With rising risk to the environment and human health, the race for biodegradable plastics is gaining pace – with several projects under way at Flinders University in South Australia.

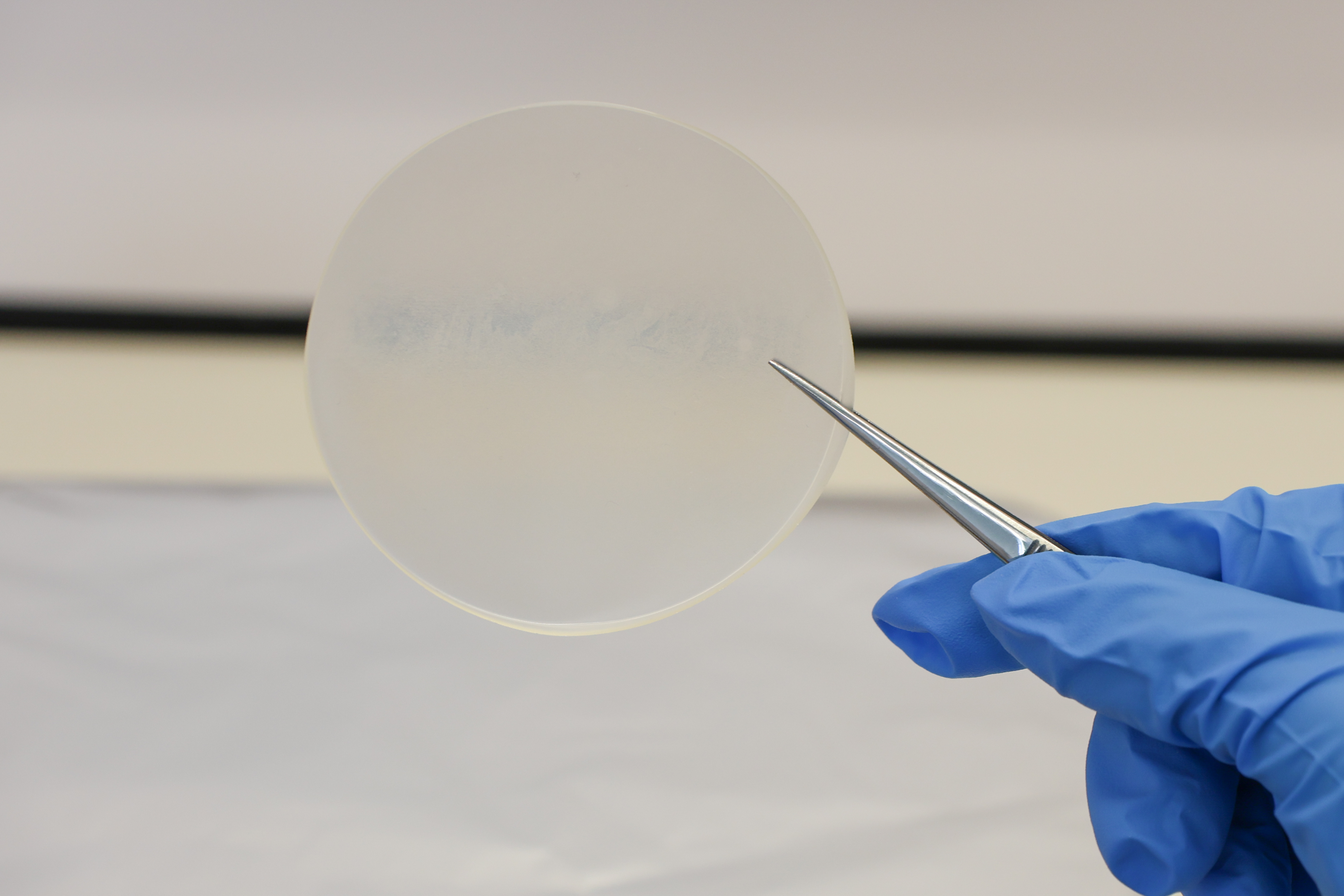

Published in Polymers, one of the latest experiments finds researchers combining calcium caseinate – a commercially available derivative of casein, the main protein in milk – with modified starch and bentonite nanoclay into a thin film, adding glycerol and polyvinyl alcohol to improve its strength and plasticity.

Biodegradability testing showed a consistent degradation trend, with full disintegration estimated to occur within 13 weeks in normal soil conditions.

This study offers exploratory insight into the development of functional and biodegradable films using biopolymer blends and nanoclay suspensions, highlighting their potential in sustainable food packaging applications.

With less toxicity, a microbial analysis confirmed that the quantity of bacterial colonies remained within permissible levels for non-antimicrobial biodegradable films.

“We would recommend further antibacterial evaluations in further testing and development,” says Professor Youhong Tang, a nanomaterials researcher at the Tonsley Campus, Flinders College of Science and Engineering.

Professor Tang, from the Flinders Institute for NanoScale Science and Technology, says that finding sustainable solutions for food packaging and other single use plastic uses is an important step towards curbing rising pollution levels.

Plastics can contain thousands of chemicals, such as dye and flame retardants, some of which are toxic and cancer-causing. The OECD has forecast that, without global action to curb plastic pollution, plastic production is likely to grow by 70% between 2020 and 2040, and eventually exceed 700 million tonnes a year.

Plastic pollution is a global crisis that no one country can solve alone – with microplastics found in soils, rivers, the air and even organs throughout the human body.

The new research was conducted in collaboration with Colombian chemical engineering researchers, Nikolay Estiven Gomez Mesa and Professor Alis Yovana Pataquiva-Mateus, from the Department of Engineering, Universidad de Bogotá Jorge Tadeo Lozano, where they were experimenting with new polymers in the Nanobioengineering Research Group in Bogotá.

“We were experimenting with caseinates to make milk-based nanofibres and found that it could be used to cast polymers similar to common packaging materials,” says Mr Gomez.

“From there, we began exploring ways to improve their properties by introducing natural and abundant components such as starch, and also a biodegradable polymer with remarkable mechanical features. This also opened the opportunity to integrate nanoclays, like bentonite, which can enhance the film’s strength and barrier performance.

“The entire formulation was designed to use inexpensive ingredients that are biodegradable and environmentally friendly to create a sustainable alternative with enhanced characteristics.”

Bogotá-based Professor Pataquiva-Mateus adds: “Everyone can play a part in reducing their plastic use, and finding biodegradable polymer alternatives is an important part of science helping to find solutions for industry, consumers, and the environment.

“Most of our single use plastic comes from food packaging, so these sorts of options should be explored further and join the circular economy revolution to conserve resources.”

Although some plastics can be reused, very little actually is. About 60% of all plastics are single use and just 10% are estimated to be recycled, according to analysis in Nature. Now used in thousands of products, plastic production is expected to keep rising from 2 million tonnes in 1950 to 475 million tonnes by 2022 – the equivalent of the weight of 250 million cars.

The article, Exploring Biodegradable Polymeric Nanocomposite Films for Sustainable Food Packaging Application (2025) by Nikolay Estiven Gomez Mesa, Alis Yovana Pataquiva-Mateus and Youhong Tang has been published in the journal Polymers (Polymer Composites and Nanocomposites section)

Multimedia

Australia; International; SA

Australia; International; SA