News release

From:

The days of dropping a thermal imaging camera and replacing an expensive lens are coming to an end with a new repairable lens developed by Flinders University scientists.

A high-performance lens for infrared cameras invented by Flinders researchers is emerging as a lower cost, more sustainable option for industries whish use thermal imaging cameras, including security and surveillance, medicine, electrical engineering, electronics, defence and autonomous vehicle operation.

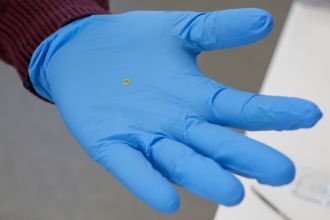

The new infrared thermal imaging lens, made from readily available and low-cost sulfur and other materials, replaces the need for traditional lenses which use expensive elements such as silicon and difficult-to-source germanium, according to new research in high-ranking international journal Nature Communications.

Thermal imaging cameras, which detect infrared light emitted from hot objects, are expanding in many practical applications and advanced technologies – from fire detection and wildlife monitoring and driver-assist or self-driving features in cars to energy-saving smart appliances.

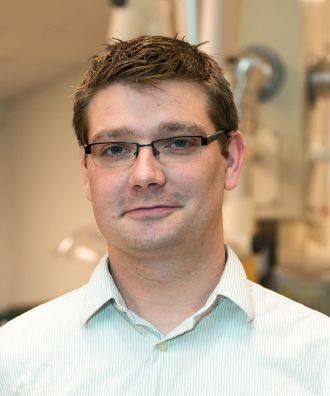

“As demand for thermal imaging in consumer products rises, there is an increasing need for lower cost optics. Our polymer lens provides a more sustainable alternative to more expensive inorganic materials such as germanium, silicon or chalcogenide glass,” explains senior author and project director Professor Justin Chalker, from Flinders University’s College of Science and Engineering.

This new polymer can be moulded like a plastic – a critical capability for mass production – and made from abundant and low-cost elemental sulfur, and an organic co-monomer material. Millions of tonnes of surplus sulfur are produced every year, and the goal is to convert this abundant byproduct from petroleum refining into value-added materials and sustainable technologies, Professor Chalker says.

“Some of the traditional lenses made from germanium cost hundreds or thousands of dollars and cannot be repaired if damaged. In contrast, our polymer lens is made from materials that are significantly cheaper. Even more, our polymer lenses can be moulded rapidly like a plastic for mass production, and they can be repaired and recycled,” says Matthew Flinders Professor Chalker.

“In fact, the raw materials used to make this lens can cost less than 1 cent per unit, so it represents an extremely cost effective, competitive alternative for the thermal camera and sensor market.”

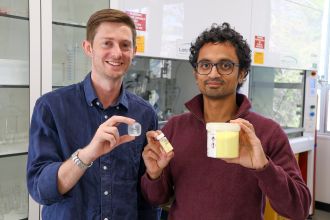

First author Dr Samuel Tonkin says the latest advances of the new lens will expand its appeal and use in consumer products such as smartphone IR cameras, fire detectors, driver-assist technology to detect pedestrians and animals at night and energy-saving air-conditioners which increasingly rely on thermal imaging.

“As the prevalence of thermal imaging in consumer products increases, there is increasing demand for lower-cost optics,” says Dr Tonkin, a Flinders University PhD graduate from the Chalker Lab. “This pioneering Flinders technology addresses the challenges by being low cost, sustainable, repairable and recyclable.”

“They can be made relatively quickly compared to the more expensive materials, such as germanium, which take time to run through milling processes and cannot be repaired if damaged,” Dr Tonkin says.

“From the first time we mounted a lens on a thermal camera and captured an image, seeing the expanding application of our research is exciting.”

The research team – including Flinders University coauthor Dr Harshal Patel (also pictured) – is working with collaborators at NASA, including another coauthor Dr Tilak Hewagama, to guide its use in imaging applications relevant to planetary science.

“This research is another big step forward in performance for this class of polymers,” adds Dr Patel. “Once these imaging systems reach consumer-level prices, they may be commonplace in fire detection systems, smart appliances, and other technologies. I’ll personally be using them to search for wildlife.”

The article, ‘Thermal imaging using sulfur polymer optics’ (2026) by Samuel J Tonkin, Harshal D Patel, Jasmine M M. Pople, Le Nhan Pham, Daniel J Lewis, Batool A Aljubran, Jason R Gascooke, Christopher T Gibson, Tilak Hewagama, Donald E Jennings, Frank T Ferguson, Martin R Johnston, Witold M Bloch, Alex C Bissember, Zhongfan Jia, Michelle L Coote and Justin M Chalker has been published in Nature Communications DOI: 10.1038/s41467-026-68889-0,

Acknowledgement: This study was funded by the Australian Research Council (DP200100090, DP210100025, DP230100587, FT200100049, FT220100054, FT240100330 and CE230100021). Further support was provided through Australia’s Economic Accelerator (AE240300053). The authors also acknowledge support from the Flinders University High Impact Collaborative Research Development Fund.

Multimedia

Australia; SA

Australia; SA