News release

From:

3D printing more realistic prosthetic eyes

A faster and less laborious method for modelling and 3D printing more realistic custom eye prostheses is reported in Nature Communications. The prostheses produced may have a more natural appearance and a better fit, compared to current methods, the authors suggest.

Approximately eight million people around the world wear a prosthetic eye, and rehabilitation can be important for psychological acceptance and physical appearance. However, the current manufacture process of custom ocular prostheses is time-consuming and requires highly skilled manual labour to hand craft each prosthesis for an individual patient. Typically, this process can require more than eight hours of work and produces prostheses of varying quality.

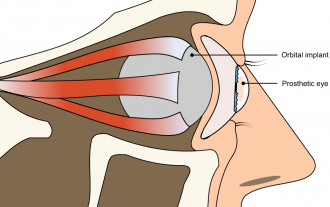

Johann Reinhard and colleagues developed and tested a digital process to produce ocular prostheses for patients requiring an artificial eye. They scanned ten patients’ eye sockets and healthy eyes using an optical coherence tomography (OCT) device, and the prosthetic was automatically shaped to fit the eye socket. Colour images were used to generate textured 3D models fabricated with a multi-material 3D printer in full colour. The print time for a single prosthesis is about 90 minutes, or about 10 hours to print 100 prostheses simultaneously. The authors were able to closely replicate the colour and anatomy of the fellow eye, in particular the colour, size, and structure of the iris, and appearance of the sclera (the white outer layer of the eyeball). While the prostheses required some final adjustments by an ocularist, the authors estimate that this approach required five times less labour compared to traditional processes and had more reproducible results.

The authors suggest that further development of this digital process could enable prostheses to be made for patients that were previously not eligible, such as children. Currently, they estimate that about 80% of patients that require an ocular prosthesis may be eligible for the described process, as the technique may currently be unsuitable for very complex sockets or certain eye conditions. These prostheses are currently the subject of an ongoing clinical trial at Moorfields Eye Hospital NHS Foundation Trust to investigate the long-term performance and impact compared to traditionally manufactured prostheses.

Multimedia

International

International